In today’s fast-paced industrial landscape, equipment reliability and operational efficiency directly impact productivity and profitability. Unexpected machinery failures not only cause costly downtime but can also compromise worker safety and disrupt entire operations. This is where Condition Monitoring Services become essential.

AMS System Solutions, a trusted leader in the field of Testing, Inspection, Certification, Quality Assurance, and Project Management, offers advanced Condition Monitoring Services designed to keep your industrial assets running smoothly and efficiently.

What Are Condition Monitoring Services?

Condition Monitoring is a predictive maintenance technique that involves monitoring the health of machinery and equipment in real-time. Using specialized tools and advanced diagnostic technologies, Condition Monitoring detects early signs of equipment deterioration—before a failure occurs.

This allows industries to:

- Minimize unplanned downtime

- Reduce repair and replacement costs

- Improve safety and reliability

- Extend asset lifespan

- Optimize maintenance schedules

Why Condition Monitoring Matters for Industries

Modern industries rely heavily on machinery. A single point of failure can halt an entire production line. Condition Monitoring helps prevent this by providing continuous insights into equipment performance.

Key benefits include:

- Early fault detection

- Improved equipment availability

- Reduced maintenance expenses

- Increased operational efficiency

- Compliance with safety and industry standards

AMS System Solutions ensures that your equipment remains reliable, safe, and efficient through world-class monitoring techniques.

AMS System Solutions Condition Monitoring Services

AMS System Solutions utilizes state-of-the-art diagnostic tools and follows international standards to deliver accurate, reliable results.

Our Condition Monitoring services include:

1. Vibration Analysis

Detects imbalance, misalignment, bearing faults, and mechanical looseness in rotating machinery.

2. Thermography & Thermal Imaging

Identifies overheating components, electrical faults, insulation breakdowns, and mechanical friction.

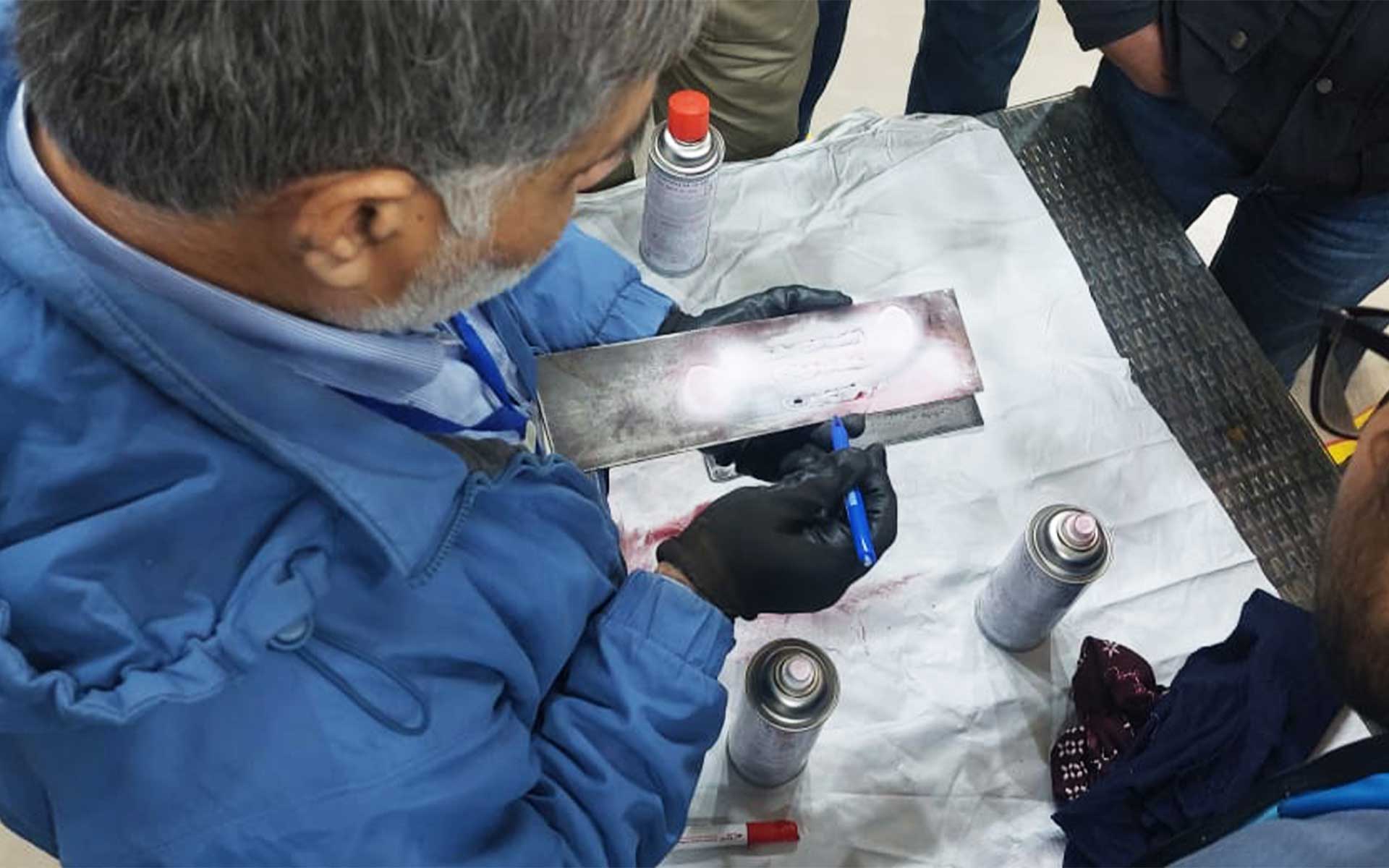

3. Ultrasonic Testing (UT)

Locates internal defects, leaks, pressure failures, and structural weaknesses.

4. Motor Current Signature Analysis (MCSA)

Evaluates motor conditions, rotor issues, and power-related faults.

5. Oil & Lubricant Analysis

Checks contamination, wear particles, and lubrication health.

6. Acoustic Emission Testing

Detects early structural damage and crack propagation.

7. Condition-Based Maintenance Planning

Customized maintenance schedules based on asset performance data.

AMS System Solutions – Commitment to Excellence

AMS System Solutions stands out as a leader in industrial reliability services. Our commitment includes:

✔ Strict adherence to global standards

✔ Advanced diagnostic tools and technologies

✔ A qualified, experienced engineering team

✔ Data-driven maintenance recommendations

✔ Cost-effective and high-precision solutions

✔ End-to-end support for clients

We ensure that every service enhances safety, sustainability, and operational efficiency.

Industries We Serve

AMS System Solutions supports a wide range of industries, including:

- Civil Engineering

- Power & Energy Sector

- Auto Manufacturing

- Electrical & Electronics

- Oil & Gas

- Warehouse & Industrial Facilities

- Machine Engineering

- Sand Blasting & Fabrication

Our solutions are custom-built to meet the specific needs of diverse industrial environments.

Why Choose AMS System Solutions?

When you choose AMS, you benefit from:

- Reliable and accurate inspection services

- Reduced risk of equipment failure

- Enhanced asset performance

- Lower operational and maintenance costs

- Expert analysis and technical guidance

We don’t just monitor equipment — we ensure that your operations remain uninterrupted and safe.